Mould Making Silicone

Silicone Mould Rubber

Support Shell Resin and Release Agent

-

Free Form AIR

Extremely lightweight epoxy putty 1A:1B by volume mix ratio. Suitable for an infinite variety of applications.

-

Plasti-Paste II

Fibre resin designed for vertical surface application. Part A is a liquid and Part B is a paste. 1A:2B mix ratio by volume, 10 minute pot life 90 minute cure time.

-

Plasti-Paste EPOXY

Trowelable support shell plastic. 2A:1B by volume mix ratio - no scale required.

-

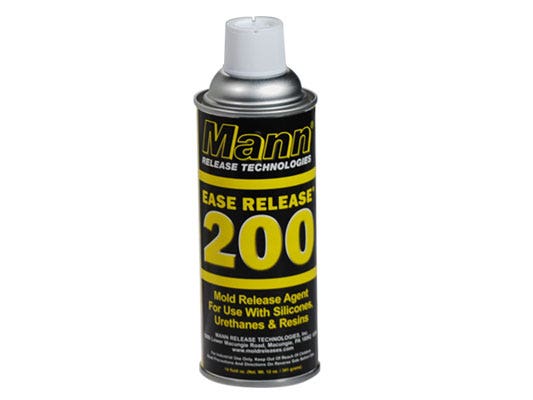

Ease Release 200

Excellent general purpose aerosol release agent for making moulds and casting parts.

-

Ease Release 205

Versatile liquid release agent that is used for a variety of general mould making and casting applications.