Silicone Rubber

Addition Cure Platinum Silicone Rubber

![]()

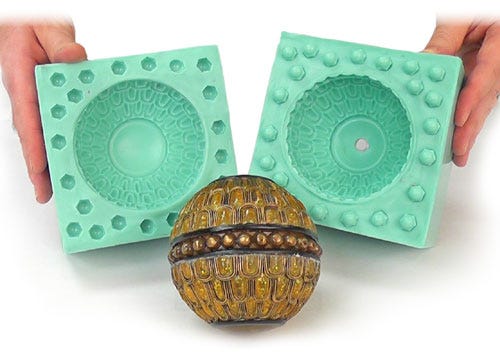

Platinum cure silicone rubbers offer the longest library life (10+ years), lowest shrinkage, and superior tear strength. Popular Mold Star series provides excellent performance for production moulds, food-safe applications, and skin-safe prosthetics. Ideal for high-quality mould making where dimensional accuracy and longevity are critical.

Condensation Cure Tin Silicone Rubber

![]()

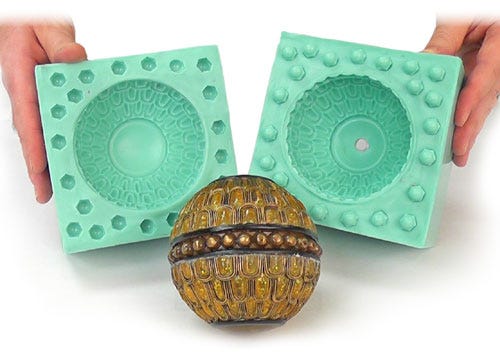

Tin cure silicone rubbers are the workhorse of the mould making industry. Self-releasing properties and excellent value make them ideal for production casting. Mold Max series offers various hardnesses for different applications. Perfect for casting urethane resins, epoxy, wax, gypsum, and low-temperature metals.

Silicone Accessories

Enhance your silicone rubber with our complete range of additives. Colorants (Silc Pig for silicones, SO-Strong universal pigments), thinners for reducing viscosity, thickeners for brush-on applications, cure accelerators, and specialty additives for custom silicone formulations and effects.