Casting Epoxy

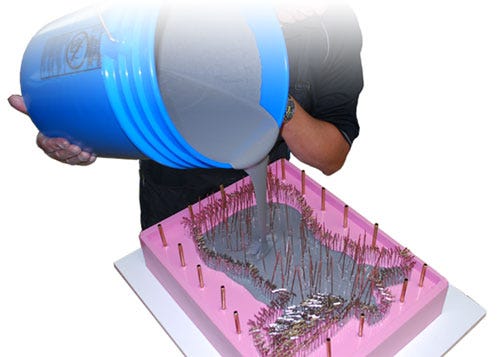

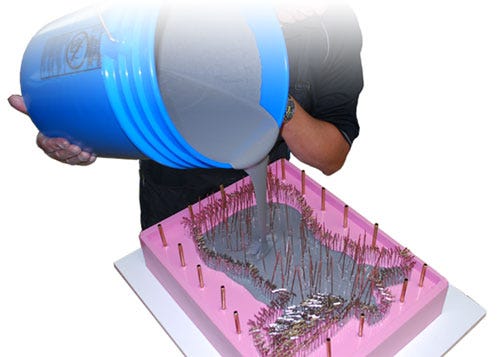

Epoxy resins are used for a variety of industrial applications and are generally stronger than other resins, offering superior physical and performance properties including higher heat resistance. Casting resins are used for making impact tooling or fixtures and are also used for encapsulating and potting applications.

Dalchem Crystal Clear Epoxy

Dalchem's Crystal Clear Epoxy Resin Kit is a premium, high-performance water-clear resin system designed for professional and hobbyist applications. This versatile 2-part epoxy system cures at room temperature to create a stunning glass-like finish that's perfect for a wide range of creative and protective applications.

EpoxAcastTM 650 and EpoxAcastTM 650 BLACK

EpoxAcast® 650 and EpoxAcast® 650 BLACK are mineral filled general purpose casting epoxies that are low cost and versatile. They feature a low mixed viscosity for minimal bubble entrapment. Choose Fast, Medium or Slow catalyst to fit your project. You can also use HT Hardener to give your castings higher heat resistance.

-

EpoxAcast 650 + 101

Mineral filled general purpose casting epoxy. Pot life of 20 minutes and cure time of 1 hour. Base and Hardener sold separately.

-

EpoxAcast 650 + 102

Mineral filled general purpose casting epoxy. Pot life of 90 minutes and cure time of 4 hours. Base and Hardener sold separately.

-

EpoxAcast 650 + 103

Mineral filled general purpose casting epoxy. Pot life of 3.5 hours and cure time of 24 hours. Base and Hardener sold separately.

-

EpoxAcast 650 + HT

Mineral filled general purpose casting epoxy. Pot life of 3 hours and cure time of 24 hours followed by heat cure. Base and Hardener sold separately.

-

EpoxAcast 650 BLACK + 101

A black mineral filled general purpose casting epoxy. Pot life of 20 minutes and cure time of 1 hour. Base and Hardener sold separately.

-

EpoxAcast 650 BLACK + 102

A black mineral filled general purpose casting epoxy. Pot life of 90 minutes and cure time of 4 hours. Base and Hardener sold separately.

-

EpoxAcast 650 BLACK + 103

A black mineral filled general purpose casting epoxy. Pot life of 3.5 hours and cure time of 24 hours. Base and Hardener sold separately.

-

EpoxAcast 650 BLACK + HT

A black mineral filled general purpose casting epoxy. Pot life of 3 hrs and cure time of 24 hrs followed by heat cure. Base and Hardener sold separately.

EpoxAcastTM 655

-

EpoxAcast 655 + 101

Aluminium filled casting epoxy. Pot life of 30 minutes and cure time of 3 hours. Base and Hardener sold separately.

-

EpoxAcast 655 + 102

Aluminium filled casting epoxy. Pot life of 75 minutes and cure time of 9 hours. Base and Hardener sold separately.

-

EpoxAcast 655 + 103

Aluminium filled casting epoxy. Pot life of 3.5 hours and cure time of 24 hours. Base and Hardener sold separately.

-

EpoxAcast 655 + HT

Aluminium filled casting epoxy. Pot life of 4 hours and cure time of 24 hours followed by heat cure. Base and Hardener sold separately.

EpoxAcastTM 670 HT

-

EpoxAcast 670HT

High temperature castable epoxy. Pot life of 3 hours and cure time of 24 hours followed by heat cure.

EpoxAcastTM 690 and 692 Deep Pour

-

EpoxAcast 690

UV-resistant clear casting epoxy. Pot life of 5 hours, cure time of 24 hours and a maximum casting thickness up to 3/8” (0.95 cm).

-

EpoxAcast 692 Deep Pour

UV resistant clear casting epoxy. Pot life of 12 hours, cure time of 72 hours and a maximum casting thickness up to 2” (5.08cm).