How to Make Hollow Resin Castings Using Smooth-Cast

So, you want to make a plastic casting of an object or sculpture but don’t know where to begin?

Semi-rigid urethane plastics (such as Smooth-Cast 57D) can be used to make hollow castings. This method of pouring molds is a highly efficient use of material and is ideal for creating highly durable and lightweight castings.

MATERIALS AND TOOLS REQUIRED FOR CASTING RESIN

If you want to learn how to make a resin cast, first, you need to gather the correct equipment. Here is what you will need:

- Mixing Sticks

- Mixing Containers

- Protection Gear (gloves, goggles, mask, etc.)

- Mold (open or closed)

- Casting Resin (Smooth-Cast)

- A Work Station

Remember – the higher in quality your equipment is, the better the finished product will be. Once you have these items, you are ready to begin your hollow resin casting.

PREPARING YOUR WORK AREA

Once you have all of the materials and tools you need for resin casting, you must prepare your work area. You need to make it as simple and mess-free as possible.

Start with the table. The table should be a good height for you – one that you feel comfortable working on. Try to use a non-stick tabletop, too, as resin can be quite messy (and sticky!). This will make the clean-up much easier.

Next, lay out all the materials and tools you need so that they’re easy to reach. You should also ventilate the area, as the fumes can be harmful to humans to breathe. Opening a couple of windows is a good idea. Now you’re ready to make a hollow resin cast.

STEP BY STEP GUIDE ON HOW TO MAKE A HOLLOW RESIN CAST

Got your silicone mold? Let’s begin! Below are easy-to-follow, step-by-step instructions for making hollow castings using Smooth-On urethane plastic.

STEP ONE – RELEASE AGENT

For easy demolding, we highly recommend using a release agent on the working surface of your mold. While urethane plastic will not bond to the surface of a silicone mold (such as Dragon Skin), using a release agent (such as Mann’s Ease Release 200) will help protect the working surface and extend the life of your mold. This is particularly important for molds intended for use over a long period of time.

For best results, spray release agent lightly and evenly over the working surface of your mold. Then, use a soft bristle brush to spread the release agent over the surface and into tight corners.

Allow the release agent to dry for 30 minutes.

Be careful not to apply too much release agent or your casting may not cure.

STEP TWO – MIXING YOUR URETHANE PLASTIC

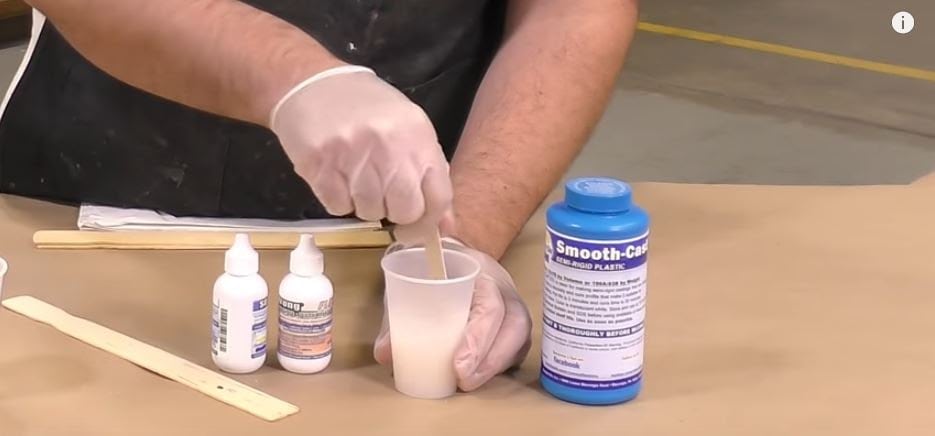

Smooth-Cast 57D is mixed 1A:1B by volume. Always make sure you measure out parts A and B in separate, clean, and dry containers.

Note: Always mix your Smooth-Cast products in a well-ventilated area. These products give off fumes that may be harmful in large quantities.

At this stage, SO-Strong tints can be added to Part B if you would like your castings to have a base tone straight from the mold. Mix your tint thoroughly with Part B to ensure a smooth and even color.

Pour both parts A and B into a mixing container and stir thoroughly.

STEP THREE – ROTATE THE MOLD

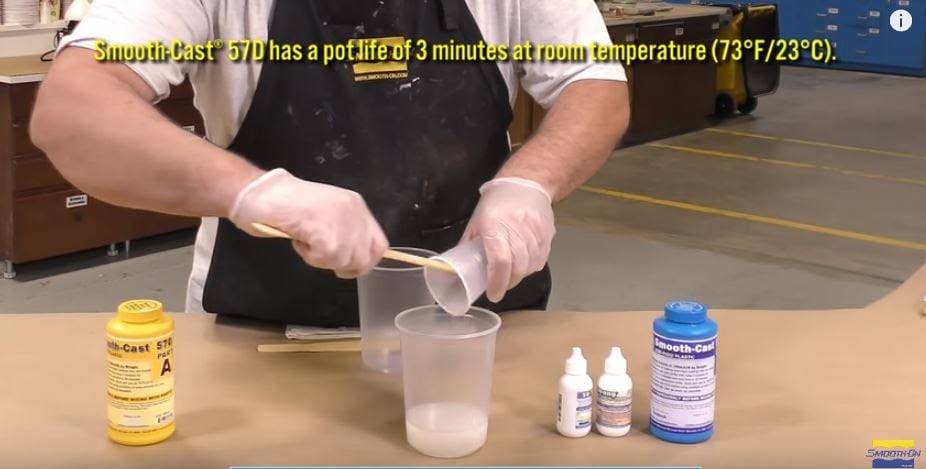

Smooth-Cast 57D has a working time, or Pot Life, of about 3 minutes at room temperature (73°F / 23°C), so make sure your mold is close at hand while mixing your urethane plastic.

Note: Excess heat or high humidity may cause your plastic to cure faster or not cure at all. Always make sure to read the instructions provided with your Smooth-On products.

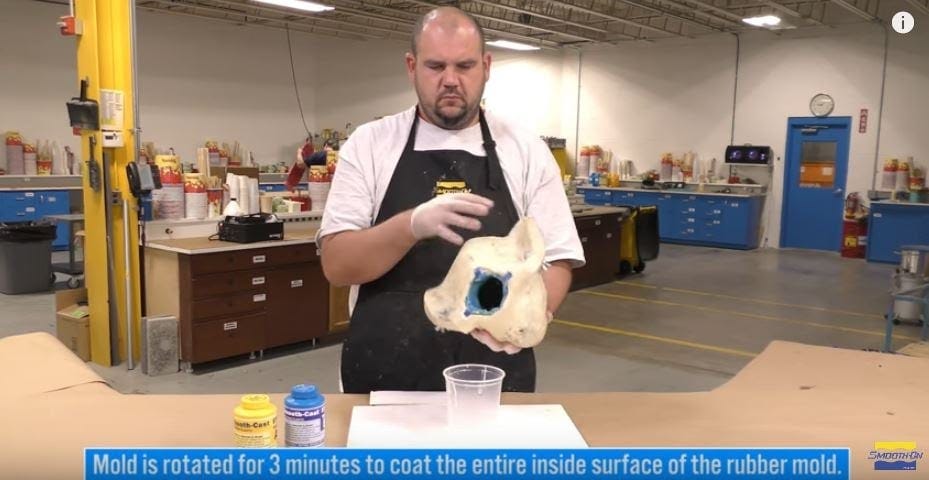

Pour the mixed Smooth-Cast into your silicone rubber mold and rotate for about 3 minutes. Try to make sure plastic coats the inside of the mold evenly, and pay special attention to raised edges where the casting will tend to be the thinnest.

Because of Smooth-Cast 57D’s short pot life, mixing smaller batches is more manageable and will make it easier to create a casting with an even thickness on all sides. For thicker castings, multiple pours of Smooth-Cast may be required.

Allow the urethane plastic to partially cure for about 8 minutes at room temperature before pouring in additional layers. It will usually take three layers to reach a thickness of ¼”.

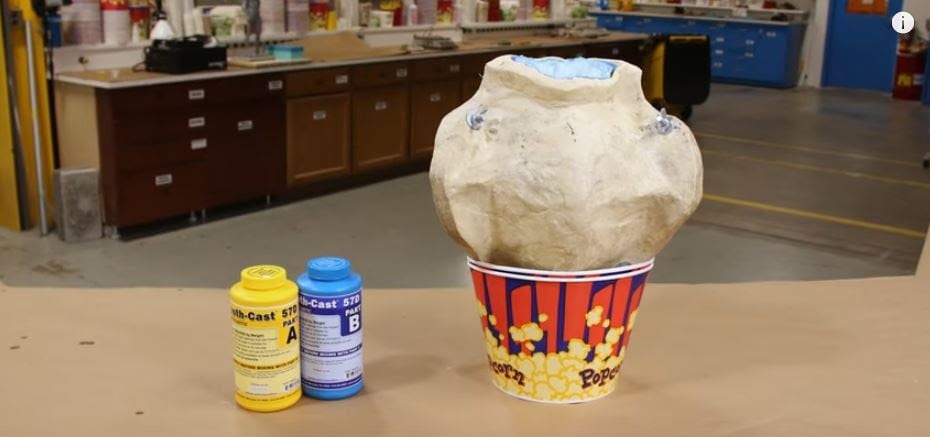

STEP FOUR – ALLOW CASTING TO SET

Smooth-Cast 57D will turn from a liquid to a solid about 3 minutes after mixing at room temperature, but it will need 30 minutes to fully cure. Castings which have thinner walls may take a bit longer to fully cure. Set your mold aside for now and allow for the urethane plastic to harden.

Note: Smooth-Cast 57D will give off some heat during the curing process. Thick or solid castings may give off enough heat to irritate skin. In some cases, protective gear may be required.

STEP FIVE – DEMOLDING

Has it been 30 minutes? Congratulations! Your hollow casting can now easily be pulled from your silicone rubber mold.

Your durable plastic casting will contain all the detail of the original object or sculpture. It can also be sanded, primed, and painted as desired.

STEP SIX – BACKFILLING AND ASSEMBLING (OPTIONAL)

For additional stability and support, hollow castings can be backfilled with rigid foam (such as Foam-It!). Foam cores will add support to a casting without adding a great deal of weight.

Smooth-Cast 57D can be bonded with other urethane plastic pieces using adhesives. Assemble multiple castings together into larger, more complicated, sculptures.

When in doubt, we always recommend creating smaller test pieces before committing large amounts of material to a full-sized casting. Testing variations, such as thickness of casting or tints, may save you time and money in the long run.

Also, always remember to wear proper protective gear when working with all Smooth-On products. Protective equipment such as gloves, goggles, and breathing protection may be necessary in some situations.

FAQ’S

HOW LONG DOES IT TAKE TO MAKE A HOLLOW RESIN CAST?

Combining everything, from setting up your workstation to pouring the resin, you should allow at least two hours. The exact time depends on your skill, of course – but you should always allow the right amount of time for the casting to set.

CAN BEGINNERS MAKE HOLLOW RESIN CASTS WITH SMOOTH-CAST?

Yes – if you are a beginner, you can use Smooth-Cast to create your very first molds. Read this tutorial carefully, though, and always put safety first. Invest in some good goggles and gloves to protect yourself!

HOW DURABLE WILL THE FINISHED RESIN BE?

With Smooth-Cast, expect your resin to be very durable. It is both easy to work with and of the highest quality, giving molders the ideal finish.

WHY DO I NEED PROTECTIVE GEAR?

Protective gear is useful when working with resin, as it will protect your eyes, hands, and lungs from fumes and substances.

Now that you know how to make a hollow resin cast, go ahead and get started! It’s so easy to do, and Smooth-Cast makes the process a whole lot easier. Whether you are a beginner wanting to try it out or you are experienced with resin, Smooth-Cast 57D is the perfect casting resin to choose.

Additional information about Smooth-Cast 57D can be found here:

For any questions about mold making, castings, or Smooth-On products, contact us via email: sales@rowetrading.com.au or Phone 08 8234 0000