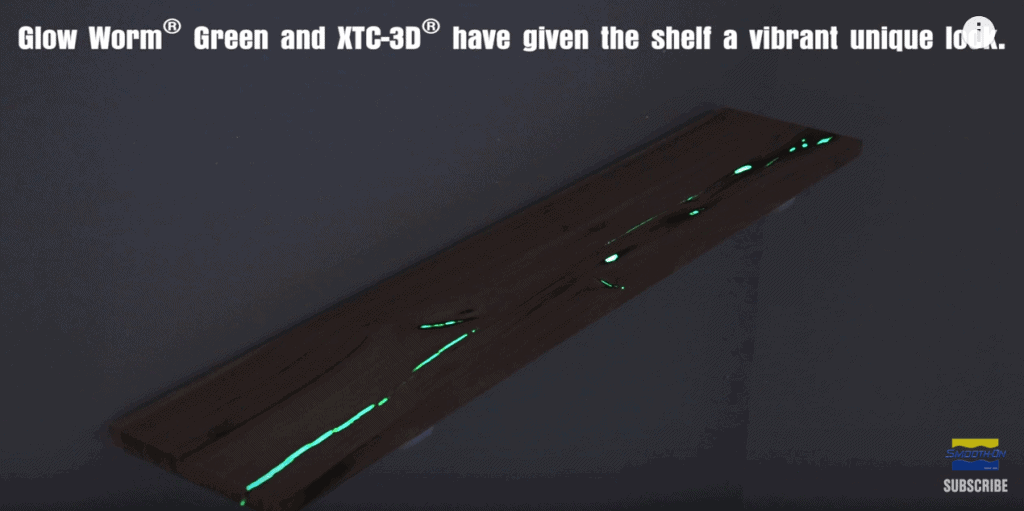

How to Make a Glow in the Dark Shelf Using Epoxy Resin

Making stunning one-of-a-kind accident shelves can be easy and fun with Smooth-On’s line of epoxy resins. In this tutorial, we will be demonstrating how to make a wood shelf with glow in the dark accents using XTC-3D epoxy resin and Glow Worm glow in the dark powder.

https://www.youtube.com/watch?v=zhCJfewREOw

Ready to get started? Here is a list of a few things you will need to complete this project:

-

Smooth-On XTC-3D epoxy resin

-

Smooth-On Glow Worm glow in the dark powder

-

Hickory Board (36” x 7” or 91 cm x 17 cm)

-

Aluminum foil

-

Mixing cups

-

Tongue depressor/Popsicle sticks

-

Isopropyl Alcohol

-

Shelf mounting brackets

-

Screws

Once you have all your supplies, it is time to get started.

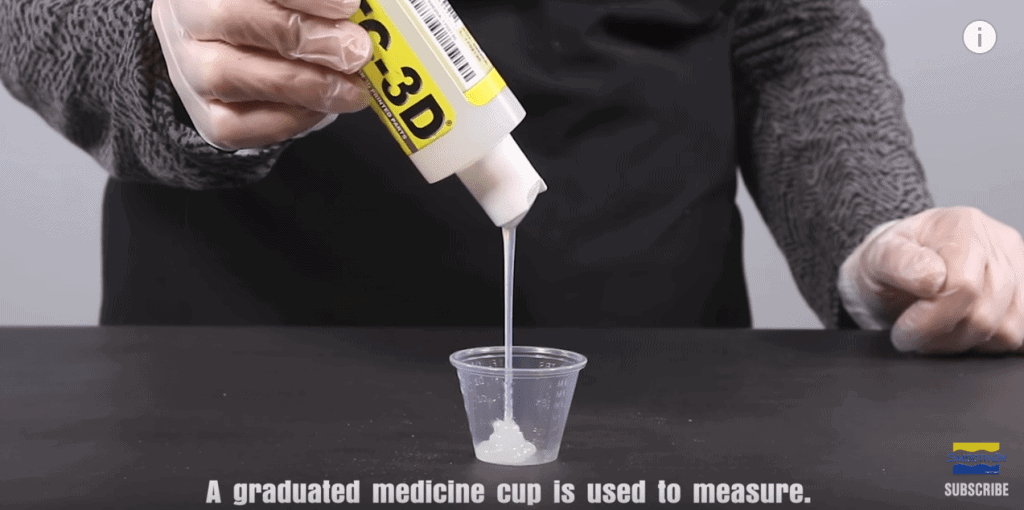

Step #1 – Dispensing the Material

For this tutorial, we will be using Smooth-On XTC-3D epoxy resin. This is a hard, impact resistant resin with minimal shrinkage when dried. Fillers and pigments can be added to XTC-3D epoxy for a variety of effects and finishes.

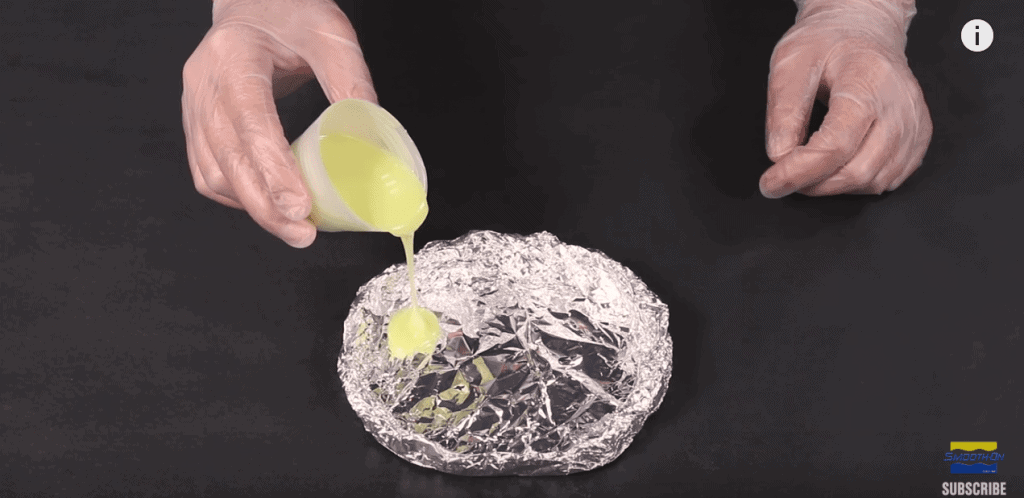

To get started, use a double layer of tin foil to make a tray for the resin.

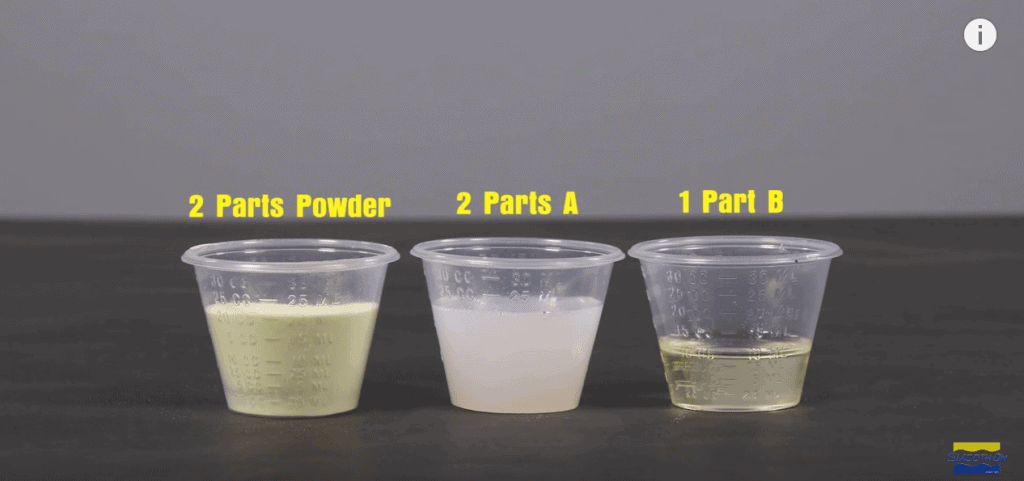

Our mixing ratio for XTC-3D will be 2A : 1B : 2 parts glow powder by VOLUME. Start by using a medicine or measuring cup to dispense 20 ml of part A. In a separate container, measure out 20 ml of Glow Worm powder. Lastly, in a third measuring cup, dispense 10 ml of part B of the epoxy resin.

Step #2 – Mixing the Material

Pre-mix the Glow Worm powder with part A of the epoxy resin first. Mix until the resin is an even and consistent colour, and don’t forget to scrape the sides and bottom of the container so there is no unmixed product.

Step #2 – Mixing the Material

Pre-mix the Glow Worm powder with part A of the epoxy resin first. Mix until the resin is an even and consistent colour, and don’t forget to scrape the sides and bottom of the container so there is no unmixed product.

Pull out the aluminum foil tray we made earlier and pour the mixed resin inside. Spreading out the epoxy and reducing its mass concentration will extend its pot life.

Step #3 – Applying the Material

Now the XTC-3D epoxy is ready to be applied to the hickory board. Using a tongue depressor, work the epoxy into the cracks in the wood panel until it is flush with the board’s surface. Any excess uncured material can be scraped away or removed by hand – just remember to wear gloves!

When you are satisfied that all of the groves in the wood are filled, clean away residue from the surface of the shelf with isopropyl alcohol.

Allow the epoxy to cure for 3.5 hours at room temperature (73F/23C)

Step #4 – Finishing Touches

The final step in this process is to buy shelf mounting brackets in the style of your choice and mount your new shelf on the wall. You’re done!

Glow Worm glow in the dark powder will charge when it is exposed to direct light, and will shine vibrant green when the lights are turned out. With Glow Worm powder, the natural texture of the hickory shelf will glow in the dark 10 times longer than other glow in the dark powders.

Get creative, and try out this technique on different types of wood for unique and dazzling designs.