Is there a way to improve surface finish when casting a rigid or flexible foam?

You can improve surface finish by applying back pressure.

Photo Examples:

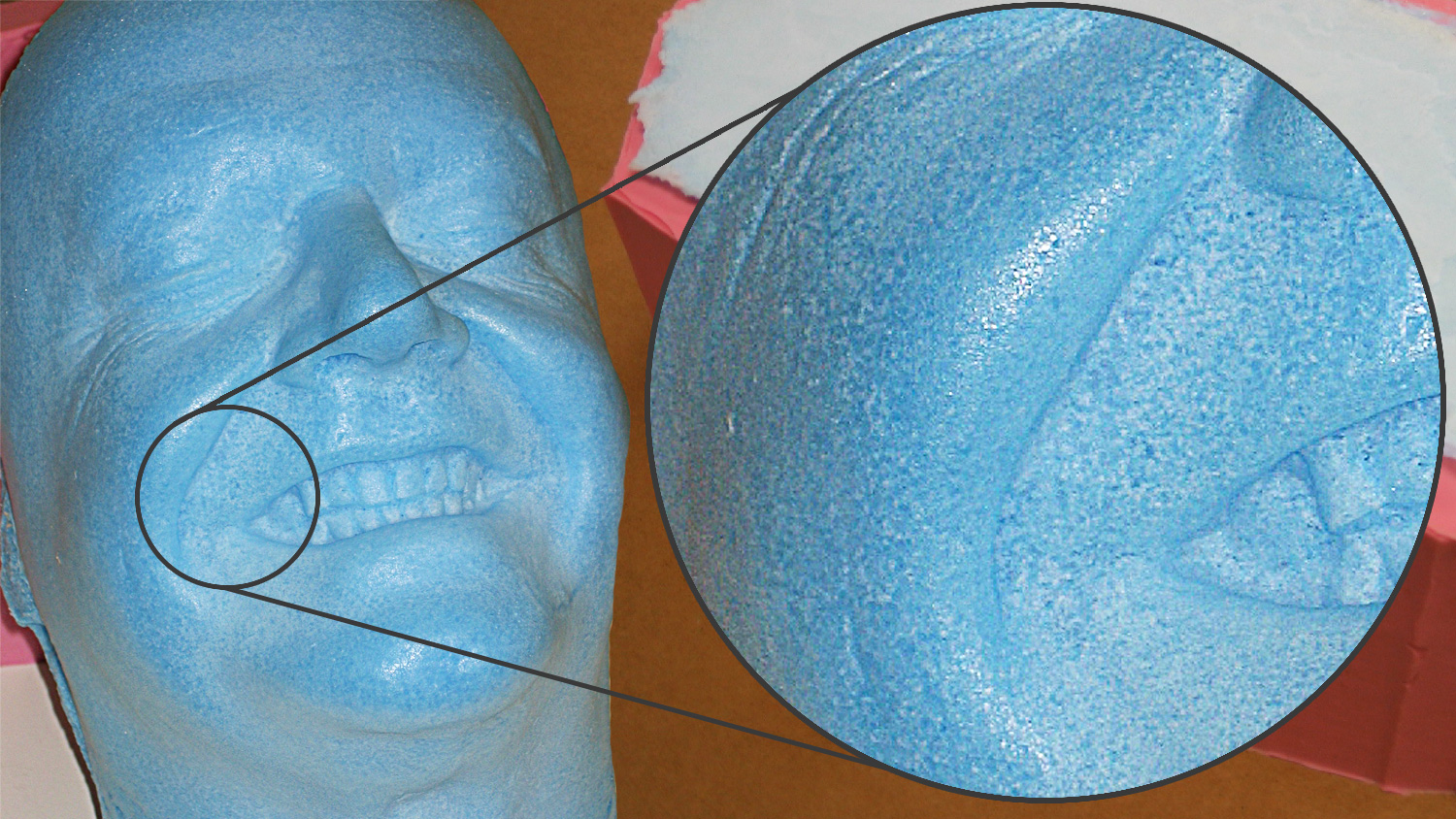

Without applying back pressure, surface finish reveals open foam cells.

Drill holes into a board that can cover mold opening during casting.

Apply Ease Release®2831 to board. Pour foam into mold and place board over mold with holes centered over cavity.

Hold board firmly in place until foam stops rising. Let foam cure for 2 hours.

Use a scraping tool to remove excess foam.

Board is removed to reveal flat back of the casting.

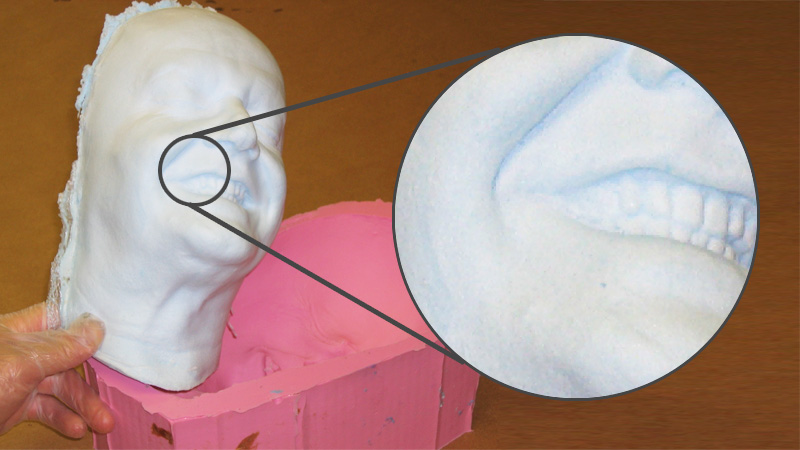

Pressure uniformly compressed foam into mold detail resulting in better surface finish.

Categories: Casting Questions