How to Make a Silicone Mould

Are you wondering how to make silicone moulds for resin? Perhaps you want to cast other materials such as foam or wax? Either way, you have landed in the right place to learn how to make a DIY silicone mould.

This comprehensive tutorial breaks down all of the materials and tools you need, answers questions you may have, lists the step-by-step process of crafting your own silicone mould, and more. Rather than relying on an external source to make it for you, take it into your own hands and design a mould that perfectly fits your specifications.

MATERIALS AND TOOLS NEEDED FOR SILICONE MOULD

- Model. The model is what will be the basis for your mould. Before you proceed, ensure this model is the right size and shape of what you hope to reproduce with the mould.

- Mold Star 15. The Mold Star™ 15 is the silicone mixture used for making the mould. This Shore 15A platinum silicone is presented in two separate parts which need to be mixed together.

- Hot glue gun. Hot glue is required for securing both the model and mould box to the baseboard.

- Mould box. The mould box can be any suitable container that is ample in covering the volume of your model. For example, if the model is small enough, this could be a plastic container with the bottom removed, effectively leaving it as a four-sided wall.

- Razor knife. For use in constructing your mould box/walls.

- Baseboard. As the name implies, this is the base for making your silicone mould. Along with keeping the mould box and model in place, it stops the silicone liquid from seeping out.

- Cups. While you don’t have to measure the mould Star 15 by weight, you do need to have equal amounts of both 1A and 1B. This can be achieved simply by using two identical cups.

- Mixing container. A well-sized mixing container is required for combining the two parts of the mould Star 15.

- Mixing stick. To mix the ingredients together in an efficient, effective manner.

PREPARING YOUR WORK AREA

In general, a silicone mould doesn’t take up much space. As seen above, making one also doesn’t require much in the way of materials and tools. As a result, a lot of space isn’t needed when it comes to your work area. While a dedicated workspace or workshop is ideal, the process can be completed relatively comfortably on a suitable table.

However, it’s still essential your work area is clean, dry, and safe. You don’t want any of your materials being affected by the elements. To prevent confusion and save time, you should also conduct a quick item count prior to beginning this project. Having all items in the open and easy to find will also make the silicone mould making process less stressful.

STEP-BY-STEP GUIDE ON HOW TO MAKE A SILICONE MOULD

Below is an easy-to-follow, step-by-step guide on how to make a rubber mould on your own. As long as you have the tools and materials listed above, you are ready to get started.

Alternatively, you can watch the video tutorial on making a silicone mould here.

-

SECURE THE MOULD

Once you have selected the model you want to make a silicone mould from, you have to ensure it is fixed into place. This works best with a model that has a flat base.With the glue gun, inject hot glue around the outside of the model’s base. Now carefully place this onto the baseboard, glue-side down, to secure it into place.

-

CONSTRUCT A MOULD WALL

As long as it is ample in covering the volume of your model, an effective mould wall can be made with a multitude of items. One of the most effective, however, is a simple plastic container. Aside from taking the lid off, all you need to do is remove the bottom of the container. This can be achieved with a razor knife, taking particular care in ensuring each side of the container is cut evenly. The last thing you want is for it to be lopsided.Once the mould wall has been constructed, secure this around your model. This is done, again, with the assistance of hot glue. Place the mould walls onto the baseboard, then while pressing down on it to keep it in place, go around it with the glue gun.

-

MIXING MOLD STAR

Mold Star™ 15 is our silicone mixture of choice. Along with a relatively low viscosity, this platinum silicone requires no vacuum degassing in most situations. Furthermore, the 65-minute pot life is extra-long for added convenience.Pour an equal amount of Mold Star’s 1A and 1B, respectively, into two separate cups. Now grab your mixing container. Add both A and B parts to the container, mixing them together thoroughly. Ensure you scrape the sides and bottom of the container to produce a consistent mix.

-

POURING

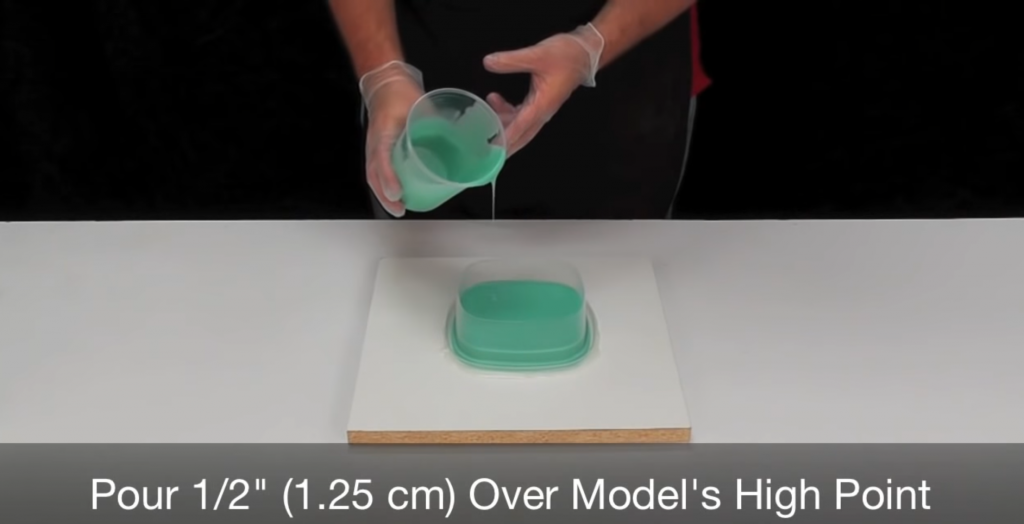

Once the mixture is ready, it’s time to pour it into your mould box. When doing this, pour it into a corner at its lowest point to produce an even coating. Also, make sure to dispense the silicone liquid into the container slowly.

-

MOULD WALL THICKNESS

As for the thickness of the silicone liquid within the mould box, it’s essential you go above the high point of your model. It’s recommended you at least go ½” (1.25 cm) above the model’s high point.

-

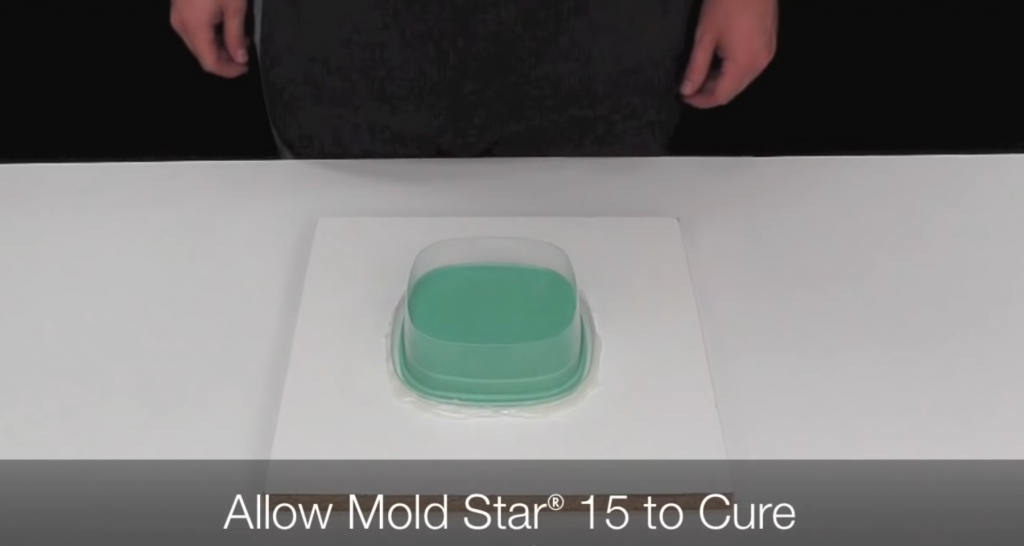

CURING

Allow the Mold Star 15 mixture to cure. At room temperature (73°F/23°C), the silicone liquid has a minimum four-hour cure time. However, it is advised you leave it to cure overnight for maximum effectiveness.Once cured, the liquid turns into a strong yet soft rubber, one which is tear-resistant and ready to use time and time again.

-

REMOVE MOULD BOX

When the curing has finished, take extra care and attention in removing the mould box. This isn’t the time where you want to damage the silicone mould. To first separate the mould from the baseboard, a tool such as a palette knife – which is both flat and thin enough to fit underneath the mould – is highly recommended.As for the mould box, place one hand onto the silicone rubber. Now gently pull at each corner of the box, continuing until all resistance is gone and the box can be removed with ease.

-

DEMOULDING

The last action you need to take is to peel back the silicone mould from your model. As with the previous step, this demoulding should be done slowly and with patience. Continue peeling until it is completely separate from the model.

-

FINISHED

That’s it. Your silicone mould is finished! It will display perfect detail, reflecting all of the design and touches of your model. Due to being produced with Mold Star 15, it’s also made to last. Shrinkage is very low over a long-term basis, which means the silicone mould can be continually used in your production efforts.

FAQS

WHAT CAN SILICONE MOULDS BE USED FOR?

A silicone mould can be used in an assortment of ways. Chefs use it to produce everything from cakes to intricate chocolate shapes. Product developers utilise silicone moulds to make prototypes, while retailers go a step further and generate custom crafts – ranging from soaps to erasers – that are ready for commercial sale.

CAN A SILICONE MOULD BE REUSED?

A silicone mould is not a one-and-done item. It is a product that can be used time and time again over a sustained period of time. Of course, the longevity of the silicone mould is dependent on the quality of materials used to make it – which is why our tutorial features the highly rated Mold Star 15 by Smooth-On.

IS A MOULD RELEASE REQUIRED?

In most cases, a releasing agent isn’t required when making your mould from Mold Star 15. However, if you do require assistance in separating the mould from the model, Ease Release 200 by Smooth-On is recommended.

WHAT IS THE BEST WAY TO LOOK AFTER MY MOULD?

To improve the lifespan of your mould, you should take the time to clean it with a soap solution and wipe it completely dry before storing it. Another tip is to place the mould on a level surface, while it is recommended for the storage environment to be dry and cool.

IN CLOSING

Making a silicone mould is accessible and easy enough for anyone to achieve. This is especially the case when following our tutorial listed above. By using the right equipment and materials, you can make the ideal silicone mould within a matter of hours.

The versatility of a silicone mould also means the possibilities are endless. You can use it for everything from food products to prototypes. Add in the simplicity of making a mould, and you won’t want to stop with just producing one! Plus, by using Mold Star 15, which is stocked on our website, you can rest assured your silicone mould is built to last.

For more silicone rubber materials check out our product range.